“After Japan and China, it is India which has the most Komori service staff” – The Noel D’Cunha Sunday Column

In the words of Komori’s chairman, Komori’s basic idea is that the sales department sells the first machine, the factory sells the second machine, and its service sells the third machine, Satoshi Mochida, president and CEO, Komori Corporation Japan, explains. You can read more in the Sunday Column

PrintWeek (PW), 2022 is behind you. What is your 2022 report card?

Satoshi Mochida (SM): 2022 was the Year of the New Normal, and the recovery in international business confidence. Due to China’s zero-Covid policy, however, the business suffered in the second half. Manufacturing costs have been impacted by the global semiconductor shortage and rising steel and energy prices. While the weaker yen has been a tailwind for our company’s overseas sales, it was not a positive trend.

PW: The years 2022 to 2020 were volatile. Which has been more challenging for you: expansion or the status quo. Lessons learnt?

SM: Covid-19 caused an economic slowdown that also affected us. Covid-19 was instrumental in digitalisation. It made it possible to see clearly what is and isn’t necessary. The same thing is happening with the printing industry. There are many printed materials that are needed, but we think paper media has great potential.

PW: What does customer development really mean to you? Which customer development case can you share with us the most?

SMIt is now difficult to create products that are globally competitive with just one product or one specification. Customer development, we believe, is about creating products that satisfy customer needs in every market and creating new business models for customers. Komori should focus on problem-solving in these situations, especially in Asia.

PW: The K in Dusseldorf and Labelexpo in India concluded on a high note. In 2023 and 2024 there are three important exhibitions: Labelexpo Europe in Brussels, Interpack/Drupa Dusseldorf and Labelexpo Europe in Brussels. What should we expect of you at these shows

SM: Drupa is our current exhibition location. Others are yet to be decided, but Komori plans to promote automation that removes the need for manual labor and increases labour productivity using the concept connected automation. At IGAS, held in Japan in November 2022, production visualisation and process linking using KP-Connect, Komori’s IoT cloud, autopilot for fully automated operation of printing presses, and logistics using a palletising robot and an AGV were demonstrated and well received.

Aside from that, I strongly support our efforts to address environmental problems. I want to speak specifically about what Komori can do in order to address rising energy costs. This is a global topic that has been discussed recently.

PW: Can paper, paperboard and label converters still manage business and manufacturing operations using industrial-age processes despite being part of the knowledge age Is there a knowledge gap within our industry? How do we bridge it? How can we convince Gen Z to use ink on paper?

SM: As I said, the paper media industry is experiencing major changes after the emergence of Covid-19. Paper containers are currently booming due to the need to eliminate plastic. However, paper media is adapting with the times and is still thriving. We are closer to creating products that appeal directly to consumers every day. I can’t imagine exactly what kind of paper media will emerge in the future, but I believe that printing technology and paper media will become even more closely related to the B2C business.

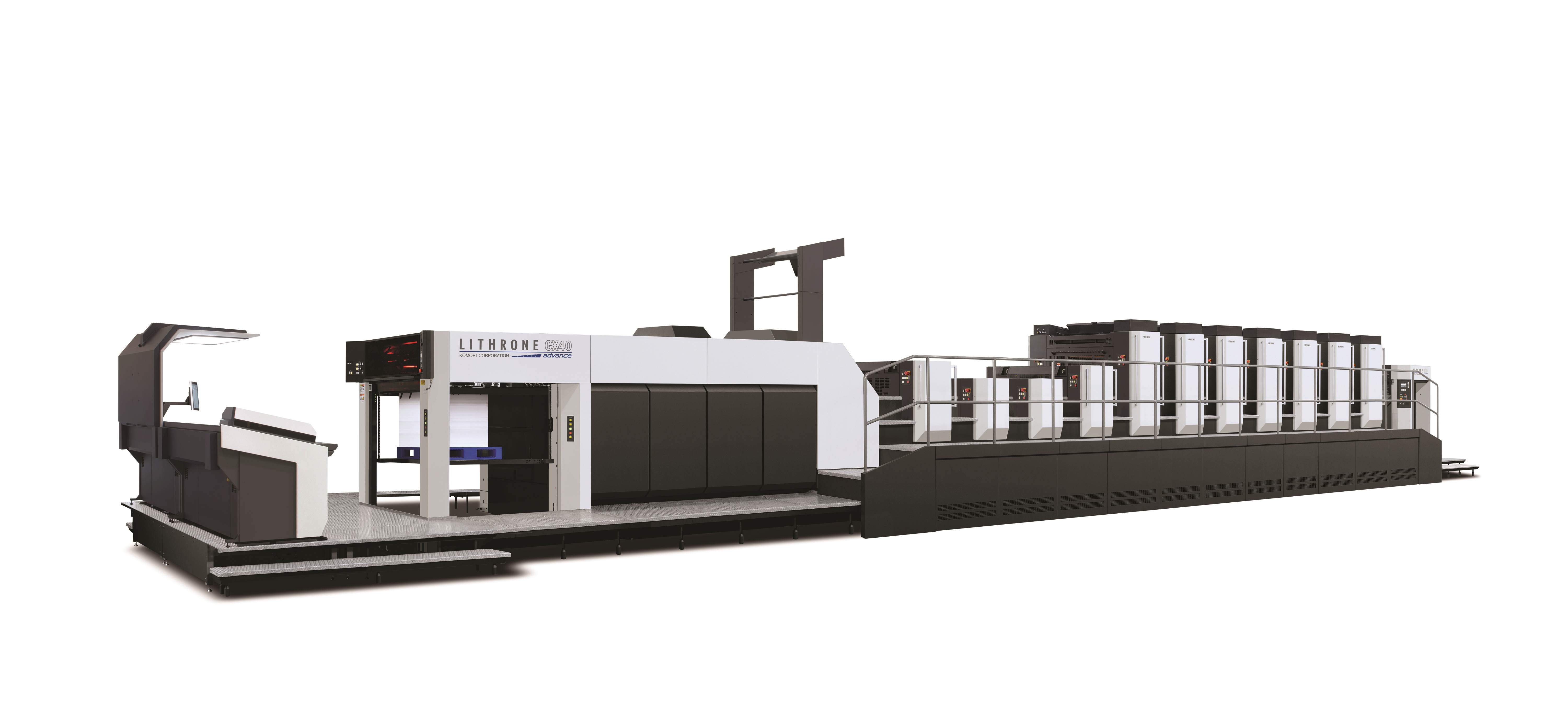

Komori Lithrone GX40 press

PW: What industry standards are there today for overall equipment efficiency (OEE). What return on investment can we expect from an OEE programme?

SM: KP-Connect can be used to determine the operating rate for printing companies. However, the OEE operating rates are generally low and vary depending on the printed material (merchandise). OEE is useful if used for one company. But it is important to look at it closely to compare it with other companies, and to set general targets values. We’d like to be able to see the production process from a wider perspective, calculate the cost of each sheet, as well as allow for judgments based on profit/hour.

PW. India is a price sensitive market. Yet, the trends are always changing. How does one remain relevant as a mass-producer of products? And what new innovations can one provide consumers to disrupt the market or create trends?

SM: Looking at India’s demographic trends, I believe that India will become a centre of global consumption in the future. Markets with growing populations tend toward standardised trends, but in today’s digital society, information from throughout the world reaches individuals. It may be more efficient to incorporate global trends quickly and present them in a format that is compatible with Indians.

PW: Would you consider remanufacturing to be a similar option? One Indian post-press equipment manufacturer successfully recycled binderies. What’s your view – advantages versus disadvantages?

SM: Printing presses’ basic components are made with durable materials that can last for decades. Remanufacturing is important for both the environment and acquisition costs. But, productivity is still a big difference between machines today and machines from 10 years ago. The quality is improving rapidly, however.

Remanufactured machines can be a headache because of the possibility of quality and breakdowns. However, new machines will increase employee motivation. New presses are more expensive because of the higher total cost-of-ownership (TCO). We hope that the customer will buy a machine with a Komori manufacturer guarantee when they purchase a remanufactured one.

PW: The F&B packaging market in India is expected to grow from USD 33.2-billion in 2020 at a CAGR (compound annual growth rate) of 9.3% until 2026. Based on our basic calculations, India’s consumption of packaged food increased by 200% over the past ten years, rising from 4.3-kg to 8-kg per person annually. A further 23% of PET applications in packaging are made by the beverage industry. India’s consumption patterns are very high. What is the best way to manage a circular economy in such conditions?

SM: The only way to achieve this is for individuals and businesses to increase their environmental awareness, and then take action under the direction of the government. The printing industry seems to be close to this activity, however. The printing industry can lead the way in creating a recycling society by switching from paper to natural materials like paper and making packaging less complicated and more useful.

PW: What can you do to address greenwashing in your circular economy and sustainability communications?

SM: We are primarily a B2B company. Our products’ environmental appeal is not often linked to consumers’ purchasing behavior. We are planning to expand the availability of environmental data in the future. We are trying to make clear the facts, based on actual data.

The Tsukuba factory consists of a factory, a research center, KGC – a learning centre – and facilities that provide benefits for the employees

PW: The structural design of packaging, which embraces a pack’s shape, texture, materials, and product delivery capability, has mostly stayed the same. How should the sector approach structural packaging innovation? New product formats, new offerings such as paneer or craft beer; and eco-friendly, longer shelf lives – MAP (modified atmospheric Packaging).

SM: Japan is an excellent example. Many people still throw away paper packaging, despite the high cardboard recycling rate. We believe that surface processes such as PP Film Laminating (which is used to increase the durability and waterproofness of paper containers) and the use plastic materials to show their contents will be reexamined in the future.

One way to counter this is to design a packaging system that encourages recycling and promotes the use of paper as packaging. The future is likely to see an increase in paper made from recycled materials like bagasse from sugarcane, fruit tree branches, and fallen leaves. I hope such paper will be used to package products in the future.

Japan has a high standard for paper container packaging. This is due to the large number of individual boxes and other characteristics. A large stock of inventory is kept to ensure that additional orders are not missed. This leads to a lot of waste due to design changes or defects.

Digital printing systems are a great way to promote on-demand printed packaging products. We believe that by producing only the amount required, we can manage smaller quantities and transform to a system that doesn’t require inventory.

PW: India’s Government has set a goal of creating a $5 trillion economy. What are your views on India’s opportunities for the printing and packaging industry and your company?

SM: Naturally, we believe India will continue to be a major global market. In anticipation of this, we established a local subsidiary here in India in 2018. But the Indian market has unique challenges. They are more challenging than those faced in other developed countries. We believe it is important to have a thorough understanding of India’s printing industry, understand Indian business, and be able identify the problems and develop products for India. One example is the Enthrone line of small, sheetfed presses that are currently being shipped to India.

PW: When the USD 3.1-trillion current economy grows to a US 5-trillion economy, India’s printing industry, and especially the packaging sector, will experience substantial growth. According to one statistic, India’s packaging use has increased by 200% in the last decade. It went from 4.3-kg per individual per annum (pppa), to 8.6 kg pppa in FY20. How ready are you to help India’s packaging and print factories?

SM: We cannot offer after-sales services for Indian markets as manufacturers introduce new products. This will cause inconvenience to our customers. India’s service staff is growing each year, surpassing China and Japan. In the words of Komori’s chairman, “Komori’s basic idea is that the sales department sells the first machine, the factory sells the second machine, and its service sells the third machine.”

PW: Too many Indian business owners focus on their investments and machines. Many people don’t pay enough attention to soft power. Culture, team building, delegation, housekeeping and how to maximize conversion costs. What is your opinion?

SM think it’s proof that consumption power is vigorous in the economy. If firms’ consumption power falls, their one-way power is diminished. Soft power can be very helpful in such cases. By defining the company’s mission and vision and clarifying the employee code of conduct, it becomes possible to direct the vector of these dispersed employees in one direction. It is crucial to do these efforts when consumption power is high. This will be a great asset for the future.

PW: Takeaway from your autobiography (if one is written)

SM: Persistence pays off.

Satoshi Mochida: at a Glance

Fav most app?

Teams.

What are some must-have items that you should always have?

A handkerchief.

Window or aisle seating?

Window seat.

Have a snack?

Meal.

Cocktail or diet drink?

Cocktail.

SUV or luxury?

SUV.

What’s the current author you are bingeing on?

DT Suzuki (An Introduction into Zen Buddhism).

What is the most impressive celeb you have met?

Chiune Sugihara (for being human and having a strong will).

What is the first thing you notice at a business meeting?

Imperfections due to prejudice and superficial analyses.

Do you have a question that you must ask before you start hiring people?

Language ability.

What’s the one thing you wish you knew at age 21?

A description of an ideal can help you to discover the root cause of a problem.

What’s the best piece of advice you’ve received?

Hold firm to one’s principles.