New nanoscale 3D printing material offers better structural protection

Science fiction depicts 3D printing as a fast process that can create new objects from any number of materials. In reality, however, 3D printing is limited in terms of the types and properties of materials available, especially for printing at very small scales.

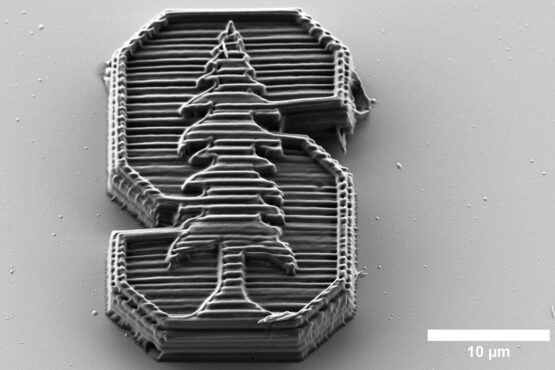

A tiny but powerful Stanford logo created using nanoscale 3D printing (Image credit: John Kulikowski)

Researchers at Stanford have developed a new material for printing at the nanoscale – creating structures that are a fraction of the width of a human hair – and used it to print minuscule lattices that are both strong and light. In a paper published in ScienceThe researchers found that the new material absorbs twice as much energy as other 3D printed materials with the same density. The researchers’ invention could be used to make lightweight protection for fragile bits of satellites, drones, microelectronics in the future.

“There’s a lot of interest right now in designing different types of 3D structures for mechanical performance,” says Wendy Gu, an assistant professor of mechanical engineering and a corresponding author on the paper. “What we’ve done on top of that is develop a material that is really good at resisting forces, so it’s not just the 3D structure, but also the material that provides very good protection.”

Introducing metal nanoclusters

To design a better material for 3D printing, Gu and her colleagues incorporated metal nanoclusters – tiny clumps of atoms – into their printing medium. Two-photon lithography is a technique where the material is hardened by a chemical reaction that is initiated by laser light. Their nanoclusters were able to jump-start this reaction, resulting in a composite material made from the metal and polymer printing medium.

“The nanoclusters have very good properties for taking in the laser light, and then converting that to a chemical reaction,” Gu says. “And they’re able to do this with several classes of polymers, so they’re even more versatile than I expected.”

The researchers were able to combine metal nanoclusters with acrylates, epoxies, and proteins – several common classes of polymers that are used in 3D printing. The nanoclusters also helped speed up the printing process. Gu and her colleagues were able print at a speed of 100 millimeters per minute by using nanoclusters combined with proteins. This is more than 100 times faster that what had been possible previously in nanoscale protein printers.

Researchers tested several lattice designs of their new material. They emphasized the ability to bear a heavy load in one structure and the ability absorb an impact in another. With the nanocluster-polymer composite, all the structures demonstrated an impressive combination of energy absorption, strength, and recoverability – essentially the ability to squish and spring back.

“The lattice structure certainly matters, but what we’re showing here is that if the material it’s made out of is optimized, that’s more important for performance,” Gu says. “You don’t have to worry about exactly what the 3D structure is if you have the right materials to print with.”

The natural world is your inspiration

Gu and her coworkers are trying to imitate what nature has done. For example, bone is made of a combination of hardness, porosity and small amounts soft material. The combination of a 3D structure with multiple well-designed materials allows bones to transfer energy efficiently and not break (most of all). It is also relatively light. 3D-printed protective structures should also be able to contain multiple types of material, including softer and harder, in order to disperse impact better and resist crushing.

“Since the nanoclusters are able to polymerize these different classes of chemicals, we may be able to use them to print multiple materials in one structure,” Gu says. “That’s one thing we’d like to aim for.”

Other Stanford co-authors include Qi Li and Ottman Tertuliano, both postdoctoral scholars, and Melody M. Wang, a graduate student. Northwestern University has other coauthors. Gu is also a member Stanford Bio-X.

This work was funded in part by the National Science Foundation and the American Chemical Society Petroleum Research Fund. It also received a Stanford Graduate Fellowship.

Subscribe to the biweekly to read all stories on Stanford science Stanford Science Digest.