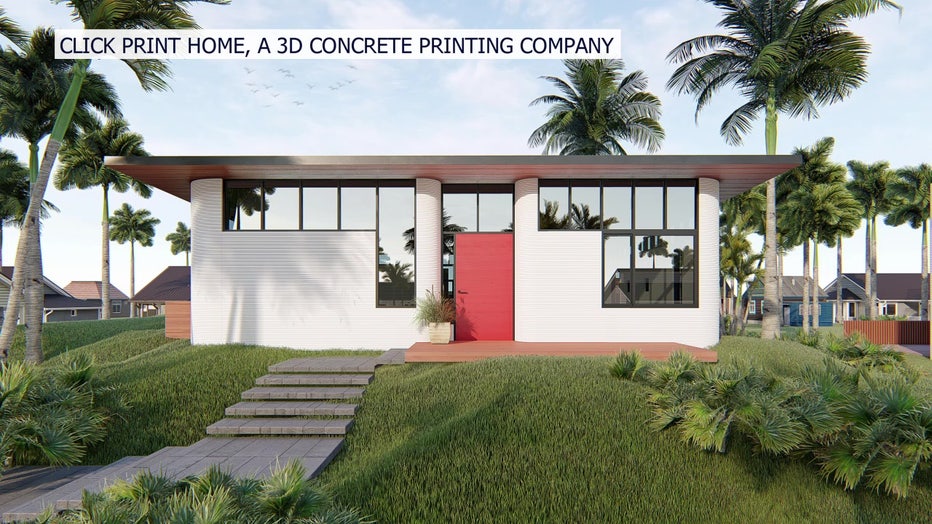

3D-printed home to be built in South Tampa

Tampa to be 3D-printed Home

Justin Matthews reports

TAMPA, Fla. – The MacDill Air Force Base will soon tear down a South Shamrock Road home. The home will be replaced by Tampa’s first 3D-printed house.

Matt Gibson, the founder of Click Print Home, a 3D concrete printer company, said that this would be the second 3D-printed Florida home.

Gibson explained that the printer is 40 feet wide and 40 feet long. Its capabilities grow and it’s actually robotic. A computer walks through the printer and puts down concrete, regular concrete and then adds layer after layer. It’s called additive manufacturing, 3D printing of concrete, just a large concrete printer, concrete is the ink.”

READ: According to market analysis, Tampa is 8th most popular place for investors to purchase houses.

Only 10 homes have been 3D printed in the United States at this time.

Gibson stated that “This is cutting-edge home construction and automation entering the construction sector.”

He stated that the technology would allow for new home production in a time of shortage of skilled labor.

“We don’t aim to replace these folks, we’re looking to augment what they’re doing right now and be able to say to ‘masons, we’ll be able to open up the designs,’ ‘we can do curvature here without a lot of work that would’ve been required traditionally,’” Gibson said.

MORE: Developer Ritz-Carlton Residences moves forward with Tampa’s second tower plan

Gibson stated that 3D-printed homes are durable and strong. They are able to support 6,000 pounds per square inch, with steel reinforcement just like masonry construction.

“Every four feet in the center you have a rebar column that’s backfilled with normal, regular old concrete, so that’s about four-times stronger than your traditional concrete block,” Gibson said.

He stated that the goal was for construction to start on the house by the end of 2023. His company is still looking for potential buyers. The home costs just $600,000.