3D Printing Industry News Sliced: Element Materials, Farsoon, Mechnano, Enable 3D, Renishaw, and more

On this version of Sliced, the 3D Printing Business information digest, we cowl the newest enterprise developments, partnerships, and acquisitions within the additive manufacturing sector.

In the present day’s version options new supplies, partnerships, and enterprise offers, and 3D printed terracotta cooler offers a contemporary but conventional makeover to air-conditioning.

Learn on for the latest updates from Ingredient Supplies, Farsoon, Mechnano, Allow 3D, Renishaw, and extra.

Supplies information from Ingredient Supplies, and Farsoon

Beginning off this week with supplies replace, world certification and testing firm Ingredient Supplies has achieved a major milestone by gaining approval from GKN Aerospace for its Antwerp laboratory. This recognition highlights Ingredient’s funding in powder characterization experience, solidifying its function within the business and increasing its capabilities in additive manufacturing. Ingredient’s dedication is obvious via its Antwerp and Teesside labs, providing ISO/ASTM 52907-compliant metallic testing providers. These labs, staffed by skilled consultants and geared up with superior expertise, give attention to important features like composition, particle measurement, and contamination. This ensures the standard of 3D printed supplies and adherence to specs. As industrial use of additive manufacturing grows, Ingredient’s labs help within the transition to energetic manufacturing from analysis and growth.

Industrial polymer and metallic laser sintering techniques supplier Farsoon has endorsed Mechnano‘s PK ESD to be used with its 252P Sequence and Flight 403P Sequence machines. PK ESD combines Jabil‘s engineered powder and Mechnano’s D’Func carbon nanotube coating, including uniform electrostatic dissipative properties to laser-sintered elements. Retaining PK 5000’s eco-friendly, impact-resistant, and chemically resistant traits, PK ESD is appropriate for practical testing and manufacturing. Enabled by D’Func, PK ESD elements obtain Nano-Uniform ESD at 107 ohms whereas sustaining mechanical efficiency and enhancing impression resistance and elongation. This development simplifies AM functions and opens new potentialities for end-use situations.

Partnership information from Desktop Well being, Renishaw, Solukon, Allow 3D

Transferring on to partnerships, Desktop Steel subsidiary Desktop Well being, and Carbon have validated Flexcera Smile Extremely+ for Carbon’s platform, increasing entry to the nanoceramic resin for dental labs globally. This collaboration marks the primary time Desktop Well being’s proprietary resin is out there to a different 3D {hardware} supplier. Flexcera Smile Extremely+ redefines digital dentistry with sturdy, lifelike restorations like dentures, crowns, and veneers. The fabric leverages proprietary long-chain chemistry for optimum dental prosthetics. Desktop Steel’s CEO, Ric Fulop, expressed enthusiasm for the partnership, whereas Carbon’s CEO, Phil DeSimone, highlighted the business’s shift in the direction of digital dentures. Flexcera Smile Extremely+ is FDA 510(okay) Class II cleared and accessible within the US, with EU availability forthcoming.

UK-based engineering agency Renishaw, in alliance with British Biking and different companions, unveils the Hope-Lotus observe bike, a cutting-edge creation set to be ridden by Nice Britain’s observe cyclists on the 2023 UCI Biking World Championships in Glasgow and the 2024 Paris Olympic Video games. The collaboration with Lotus Engineering and Hope Expertise concerned bespoke parts like aerodynamic forks and handlebars. Renishaw’s additive manufacturing experience quickly produced plastic and metallic prototypes for aerodynamic testing, with elements refined for energy and geometry. This alliance showcases how expertise enhances bike efficiency, providing optimized design for particular person athletes. The light-weight, superior bike goals to safe invaluable marginal positive factors in competitions, enhancing British athletes’ efficiency.

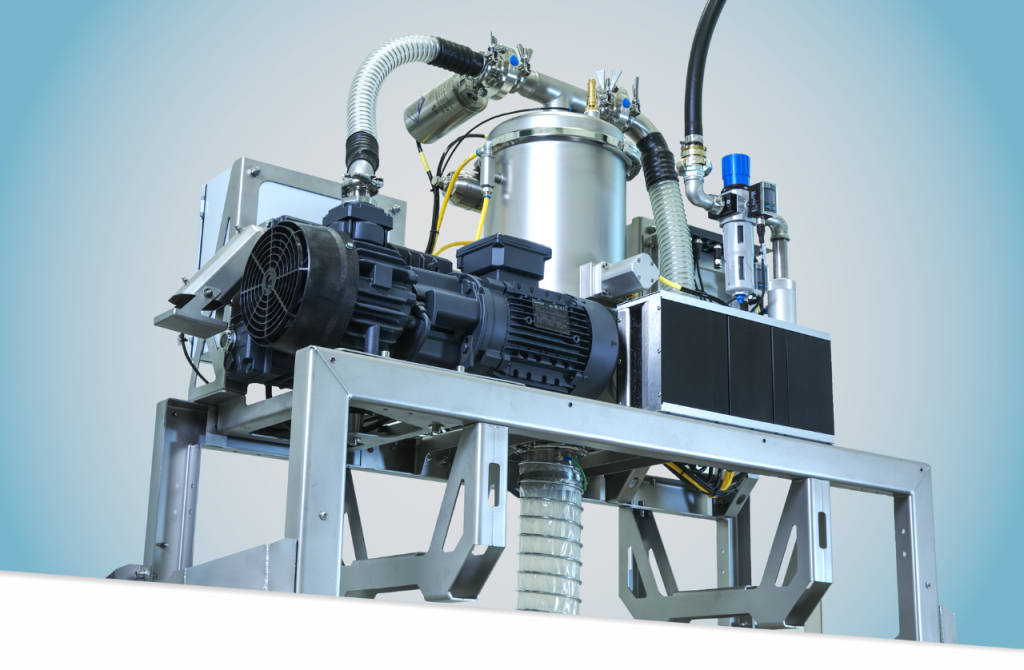

Reichenbacher and Solukon have collaborated to reinforce the postprocessing of 3D printed metallic elements by automating each unpacking and depowdering. This joint effort integrates the elimination of unfused powder from complicated buildings. The method begins by loading all the container with the half into the SFM-AT1000-S. The container is rotated and emptied of unfastened powder, which is then ready externally. Following this, Solukon’s system employs SPR expertise for cleansing utilizing exact actions calculated from the half’s CAD file. The answer handles containers weighing as much as 800 kg and employs high-frequency vibration to deal with difficult powder clumps throughout the half’s inner channels.

Hungarian designer Adam Miklosi has collaborated with Allow 3D for Uppgradera Assortment 3, a sequence of IKEA hacks created via 3D printing. Miklosi attracts inspiration from IKEA merchandise to reinforce designs and deal with points. The gathering gives free downloadable designs for home-based 3D printing, emphasizing shopper participation in creation. Allow 3D’s method disrupts conventional worth chains, selling co-production and a round financial system with totally reusable mono-materials. The collaboration goals to amplify consumer expertise and revolutionize consumption via progressive, consumer-driven designs.

Enterprise offers and acquisitions from Cadpro, AML3D, and Phase3D

Diving into enterprise offers and acquisitions, Cadpro has acquired Australian Cross Expertise Group for enhancing CAD expertise and providers within the Australian design and engineering sectors. With experience in Autodesk product consulting and coaching, Cross Expertise enriches Cadpro’s choices for an improved buyer expertise. Hans Grootegoed, MD of Cadpro, welcomes the addition, aiming to amplify capabilities throughout ANZ, driving digital transformation in structure, engineering, building, design, and manufacturing. Purchasers retain entry to software program and help, whereas new crew members and broader experience create thrilling potentialities. Doing so, amplifies buyer excellence and knowledge-sharing, strengthening each entities out there.

Australian large-format 3D printer producer AML3D has bought its ARCEMY ‘X-Version 6700‘ Wire Arc Additive Manufacturing (WAAM) metallic 3D printing system to the U.S. Navy’s Additive Manufacturing Middle of Excellence (AM CoE) in Danville, Virginia. The AUD$1.1 million (US$771,686) order, facilitated by AML3D’s value-added reseller Philips Company, goals to reinforce the U.S. Navy’s provide chain and industrial base resilience. The ARCEMY X system is about for set up by early 2024, reinforcing the Navy’s dedication to adopting superior additive manufacturing applied sciences for progressive and aggressive progress in protection and submarine sectors. This second ARCEMY X order showcases the Navy’s belief in AML3D’s capabilities.

Moreover, AML3D has secured a European patent for its WAM course of, aligning with its Australian patent. This patent from the European Patent Workplace covers AML3D’s method to crafting 3D metallic elements, enhancing its mental property safety and reinforcing its standing in superior metallic 3D printing. Notably, AML3D stands as the only additive manufacturing entity with a European course of patent, solidifying its place as a Wire Additive Manufacturing expertise chief on the continent, says the corporate. Whereas concentrating on increasing ARCEMY system gross sales to U.S. Protection, Marine, and Aerospace sectors, AML3D intends to increase its affect to European industries, providing time and cost-efficient custom-made parts to bolster provide chains.

“It is a important milestone for our firm and our expertise journey. The granting of this patent is additional validation of our proprietary expertise and likewise secures our place as a worldwide supplier of a serious industrial metallic 3D Printing course of. The market demand for superior wire feedstock additive manufacturing, that may deal with provide chain threat, ship time and price financial savings and higher ESG outcomes continues to speed up. This extra worldwide course of patent safety will additional strengthen our place in a major and rising addressable market,” stated AML3D Interim CEO Sean Ebert.

Chicago startup Phase3D has secured a $1.25 million, two-year contract from the Air Pressure Analysis Lab (AFRL) to develop an inspection system for chilly spray additive manufacturing (CSAM). This expertise, slated for set up at South Dakota’s Ellsworth Air Pressure Base, holds promise for environment friendly defense-related half manufacturing and restore. Presently, gathering goal information throughout CSAM poses challenges. Phase3D’s flagship Fringe in-situ inspection system might be tailored to make sure uniform materials deposition, fostering broader CSAM adoption by offering repeatable, quantifiable information. Collaborating with VRC Metals, Phase3D goals to validate structured mild measurements, providing real-time high quality monitoring for CSAM’s functions.

3D printing functions updates from Mechnano, and Entreautre

Amid rising world temperatures, air con has shifted from luxurious to very important want, however environmental issues persist. In response, designer Simon Pavy and world company Entreautre teamed up for an eco-friendly answer: the low-tech terracotta cooler. This idea attracts inspiration from historical cooling practices seen within the Center East, India, and Egypt. A 3D printed, porous terracotta vessel varieties the core, using nature’s evaporative cooling rules. Leveraging Grasshopper software program and ceramic 3D printing, designers improve performance and aesthetics. The cooler’s potential to revolutionize cooling strategies for sustainability and luxury highlights the harmonious mix of custom and innovation. The low-tech terracotta cooler signifies hope for a greener, cooler world amid local weather change challenges.

Arizona-based 3D printing firm Mechnano introduces D’FuncTM, its trademarked proprietary course of that enhances electrical and mechanical efficiency in groundbreaking additive manufacturing masterbatches and supplies. With over 130 patents, D’Func addresses challenges attributable to “soiled tubes” (clumped CNTs), bettering AM materials properties. It gives Nano-Uniform ESD safety, countering insulative pockets, lightning rod results, and residual metals in ESD functions. The time period “D’Func” originates from Mechnano’s R&D lab, reflecting its “dedication to progressive options.” D’Func assures consistency and reliability in Nano-Uniform ESD properties, emphasizing its significance in defending delicate electronics inside AM supplies.

Certifications information from Makers Empire, Axial3D, and MakerVerse

Australian EdTech firm Makers Empire, achieved B Company (B Corp) certification, validating its dedication to optimistic impression. Identified for creating main EdTech merchandise for faculties, utilizing 3D expertise to have interaction college students in STEM and design considering, Makers Empire now joins over 560 B Corp companies in Australia and NZ, and seven,000+ globally. B Lab’s rigorous evaluation course of evaluates social and environmental efficiency. This certification underscores adherence to excessive requirements for impression, governance, accountability, and transparency. Makers Empire’s user-friendly 3D design software program, utilized by 2.8+ million college students throughout 50+ nations, enhances spatial reasoning, reduces STEM nervousness, and fosters creativity. It’s backed by analysis and partnerships for widespread STEM studying.

Medical segmentation and 3D options supplier Axial3D has secured FDA clearance for an automatic, AI-driven cloud-based platform for orthopedic trauma, maxillofacial, cardiovascular, and orthopedic functions. This marks Axial3D’s second FDA clearance for its INSIGHT segmentation platform, a breakthrough in healthcare’s adoption of AI and automation for personalised affected person care. With its AWS cloud infrastructure and AI algorithms, INSIGHT converts 2D DICOM pictures into correct 3D visualizations, mesh information, or 3D printed anatomical fashions. By streamlining picture segmentation, Axial3D empowers healthcare suppliers and medical system companies, bettering diagnostic accuracy, therapy planning, and surgical interventions, whereas enhancing patient-specific packages and accelerating the design of personalised gadgets.

Industrial elements sourcing platform MakerVerse has achieved ISO 27001:2017 certification for data safety. This globally acknowledged customary validates its strong data safety administration system (ISMS) overlaying controls, information safety, and continuous enchancment. TÜV SÜD‘s rigorous audit assessed MakerVerse’s ISMS, together with safe growth practices, entry controls, and cryptography. This achievement highlights MakerVerse’s dedication to top-tier information safety and customer support, including to its ISO 9001 certification for high quality administration.

Distribution offers updates from Meltio and AddUp

Steel 3D printer developer Meltio has formally appointed IRTI Robotics as its gross sales companion. The partnership will see IRTI Robotics tackle a vital function in integrating and supporting Meltio’s Engine Robotic answer throughout the Indian market, notably for Steel Additive Manufacturing. Meltio’s distinctive metallic 3D printing method employs welding wire as a feedstock. IRTI Robotics’ focus might be on seamless integration and enterprise growth, collaborating with academia, tooling machine corporations, and business gamers to reinforce Meltio’s presence and choices in India.

Industrial metallic 3D printer producer AddUp has built-in Constellium’s Aheadd CP1 aluminum alloy into its FormUp 350 machines, broadening its materials choice for additive manufacturing. Aheadd CP1, developed for laser powder-bed fusion (L-PBF), gives improved productiveness and warmth dissipation in comparison with standard aluminum alloys like AS7 and AS10. This alloy streamlines post-build processes, requiring a easy 400°C warmth therapy. With mechanical properties akin to AS7 and enhanced thermal conductivity, Aheadd CP1 holds promise for aerospace functions, doubtlessly increasing its utility past motorsports. The fabric’s success in motorsports hints at wider industrial functions, supported by the efficiency of AddUp’s FormUp 350 system.

Pennsylvania State College brings information for the medical sector

Pennsylvania State College (PSU) researchers spearheaded a venture to develop superior bioprinting expertise able to effectively producing human tissues at a big scale. With a $2 million grant from the Nationwide Institute of Biomedical Imaging and Engineering on the Nationwide Institutes of Well being, the crew, led by Professor Ibrahim T. Ozbolat, goals to create the first-ever system for fabricating native tissues, together with bones, tracheas, and organs. Constructing on earlier work with mobile aggregates, the expertise, named “high-throughput spheroid bioprinting,” will allow simultaneous printing of a number of cell clusters, boasting excessive accuracy and unprecedented pace. This interdisciplinary effort combines experience in bioprinting, biomaterials, and tissue engineering.

“This expertise, as soon as totally developed, could be utilized for the fabrication of quite a lot of human tissues,” stated co-principal investigator Elias Rizk, a professor of neurosurgery at Penn State Faculty of Medication. “It may very well be cardiac tissue or lung tissue. It may very well be pores and skin and even bone, which is tissue. This expertise may restore bone in a speedy method, even in delicate locations just like the cranium.”

PUNCH Torino makes use of Markforged’s simulation device to enhance 3D printing course of

European R&D and engineering hub PUNCH Torino has enhanced its 3D printing course of utilizing Markforged‘s Simulation device. The problem was producing correct prototype engines with exactly timed parts. The crew designed specialised camshaft locking instruments constructed from strengthened Onyx with fiber to stop camshaft motion throughout tightening, guaranteeing synchronization. Beforehand, this demanded quite a few device iterations and substantial time funding. With Markforged’s Simulation, PUNCH Torino has lowered the typical iterations from eight to a few, saving about 18 hours per jig, streamlining engineering modifications, and optimizing fiber association. This device reveals potential for refining half design and bettering deliveries for PUNCH Torino’s clientele.

AM automates design and manufacturing, mitigating handbook labor wants

UK’s offshore power business, Offshore Energies UK (OEUK) revealed a report in December 2022 emphasizing a expertise scarcity throughout the business. Additive manufacturing, nonetheless, gives an answer to the dearth of experience by automating design and manufacturing, mitigating handbook labor wants. Dave Moore, 3D print marketing consultant at Tri-Tech 3D, a UK supplier of Stratasys, One-Click on Steel, and XJet 3D printing options, explains how AM can deskill oil and gasoline half manufacturing. With superior supplies and techniques, AM extends to the manufacturing line, facilitating functions like funding casting, sand casting, and composite layup instruments, alongside optimizing turbo equipment, rotors, and different parts. This shift towards AM presents a promising path to handle expertise shortages within the offshore power sector.

Bond3D introduces a novel answer to materials shrinkage in 3D printing

Dutch 3D printing firm Bond3D, collaborating with AniForm, has launched a singular answer to a standard 3D printing problem – materials shrinkage throughout cooling. Typical supplies like PEEK contract by 3.5% upon cooling, usually resulting in print inaccuracies. Bond3D’s innovation includes a customized software program answer that calculates and compensates for native shrinkage and warping through the printing course of. By adjusting the toolpaths in three dimensions – X, Y, and Z – the expertise ensures that the ultimate cooled product precisely aligns with the supposed design. This development not solely reduces the necessity for post-processing but additionally streamlines design iterations, curtails materials waste, and notably shortens lead occasions.

Volkmann USA unveils vDryer, a Vacuum Dryer for metallic powders

US-based 3D printing tools producer Volkmann USA has unveiled the vDryer vacuum dryer. Designed to reinforce metallic half manufacturing high quality, the vDryer restores metallic powders to the required moisture content material degree for construct jobs. Utilizing electrical vacuum pump expertise, it swiftly removes moisture with out making use of warmth. Examined by BMW Group for higher 3D-printed metallic elements, the system could be positioned upstream or downstream from printers, bettering powder high quality. It’s complemented by Volkmann’s pneumatic vacuum conveyors to seamlessly switch dried powder for storage or printing.

What does the way forward for 3D printing for the subsequent ten years maintain?

What engineering challenges will should be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Business e-newsletter or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you in search of a job within the additive manufacturing business? Go to 3D Printing Jobs for a collection of roles within the business.

Featured picture reveals 3D printed bike on the observe. Picture through Renishaw.