“Digital also enables one-to-one; versioning and variable to be more attractive to consumers” – The Noel D’Cunha Sunday Column

Jeff Jacobson (CEO and chairman of Electronics For Imaging) says that there are many positives in EFI for 2022. “With 50 installations worldwide, the Nozomi single-pass product line continued to stand out globally,” he says. In this interaction, Jacobson discusses progress in Fiery, its growth in textile, print’s digital transformation and how Covid accelerated that transformation even in the corrugated packaging space, as it moved everyday purchasing activity into the realm of eCommerce.

PrintWeek (PW: 2022) is behind us. What’s your 2022 reportcard?

Jeff Jacobson, JJEFI is currently reviewing our activity and progress throughout the year. It is possible that it is unfair to give a grade for our final exams as we have not yet had them. But when I speak about our activity and progress in 2022 soon – in town halls with our staff and in meetings with our investors – much of the discussion will be about our strengthened commitment and purpose as a print and packaging technology leader. We began 2022 with a realignment – including spinning off our MIS/ERP business – to fully focus on the analogue-to-digital transformation while creating new opportunities in industrial print.

PW: What are the Positives?

JJ: In 2022, there were many. Packaging with the Nozomi single-pass line of products continued to stand out worldwide. There are now 50 installations around the world, with a compact, 1.4-metre-wide Nozomi model.

Our Fiery business also launched a significant new partnership to develop Fiery digital front ends (DFEs) for Fujifilm Business Innovation’s Revoria digital presses in APAC and in most of Europe.

We also made two acquisitions last summer to grow in our digital leadership capabilities, with the Fiery business acquiring one of North America’s top direct-to-garment and direct-to-film digital workflow providers, CADlink, and our Reggiani business buying the world’s leading textile RIP developer, Inèdit.

EFI leaders were able to manage difficult supply chain challenges. They set the table for 2023 as the backlog resulting from the supply chain problems flows through. We are currently upgrading our Spanish plant, which produces many of the display graphics and industrial printing machines. In Italy, our EFI Reggiani textile operations can be found, we have opened a new facility near Milan which will increase energy efficiency and improve printer manufacturing.

PW: The years 2022 to 2020 were volatile. What has been the outcome for you? Did it be expansion or status quo.

JJ: The past two years have not been like the status quo. The past two years have seen significant changes due to Covid, lockdowns and the war in Ukraine. Supply chain issues, inflation at levels never seen in 40 years and more are all reasons why the industry has been affected. You can still innovate and progress, but that doesn’t mean you shouldn’t. It is simply not possible to effectively approach digital printing markets from a status quo mentality. Demand has remained strong in segments like packaging and display graphics.

There is so much opportunity ahead for print’s transformation to digital. Covid helped accelerate the transformation of corrugated packaging as it moved daily purchasing into eCommerce. Due to the rapid pace of change, our customers who use EFI Nozomi single pass inkjet packaging presses have continued to see double-digit percentage increases in their output on average.

PW: If you go back two full years to the beginning of 2020, at that point, it was your first year as EFI’s CEO. What lessons can we learn?

JJ: It was an intense process of learning, investigating and, yes, changing for me. EFI was something that I was familiar with because I had been a partner in my previous roles. My focus was on our markets, opportunities, and more. The best way forward was to put more emphasis on digital printing. To do this, we increased our technology and service capabilities for Fiery and Inkjet products.

our customers can take the full advantage of digital print’s promising opportunities.

PW: What does customer development really mean to you? Which customer development case can you share with us the most?

JJ: Avantika Printers may be known to PrintWeek readers. This printer has been able to thrive and evolve by remaining on the forefront of technology. The company first adopted EFI Fiery DFEs in 2008 and since then has earned PrintWeek’s Best Digital Printer Award several times. Fiery has an excellent education, training and certification programme, and Avantika’s director Himanshu Pandey is a Fiery-certified expert who has established his company as leader in digital colour management. Avantika’s initial success in the photobook market was due to this high level of colour management knowledge.

Avantika’s expertise in packaging applications was extended to its Greater Noida facility in 2022. Avantika is the only business in the world to have achieved Ghent PDF Suite 5.0 Conformance certification using a new service EFI that was developed in collaboration with Ghent Workgroup.

Avantika customers who embrace digital technology and are open to new possibilities with it develop a reputation of excellence. When a print company can achieve this level of excellence and is recognized as the best in the field, it can be a competitive advantage and open up the doors to further growth and innovation.

PW: The K in Dusseldorf and Labelexpo in India concluded on a high note. There are three major exhibitions lined up for 2023-2024: Labelexpo Europe, Brussels and Interpack/Drupa Dusseldorf. What should we expect of you at these shows

JJ: Expect strong attendance at tradeshows. Virtual events have not been well received by consumers in recent years. As a result, tradeshows are attracting more people. Printing United in America was a great example of this. I witnessed it in the crowds.

We were in Greater Noida exhibiting important industrial textile solutions to India ITME. India and all of South Asia are very important for our EFI Reggiani industrial textile business, and textile – a market with relatively little digital print but tremendous growth opportunity – has become a key area of investment for us.

EFI hosts an additional event that is just as important. Our Reggiani business is exhibiting at ITMA in Milan in June, and it will be EFI’s largest tradeshow of 2023. We are also excited about Drupa 2024. While I can’t disclose anything, Drupa has the potential to be a game-changer in terms of the digital technologies we will present to our customers, particularly in the display graphics and packaging spaces.

PW: Do paper, label and paperboard converters still manage their business and manufacture operations with industrial-age methods despite being in the knowledge age? Is there a knowledge gap within our industry? How do we bridge it? How can Gen Z be convinced about the efficacy of ink on papers?

JJ: As new digital-first thinkers enter the industry, it will be even more digitally-oriented. However, it is important to ensure that these young people actually enter the industry. Many of them have outdated views of packaging and printing, and don’t see it as a career. We cannot lose sight of how important it is to bring in fresh talent, and fresh thinking, to continue the industry’s digital transformation.

PW: What industry standards are there today for overall equipment efficiency (OEE). What return on investment can we expect from an OEE program?

JJ: It can be complicated to discuss and may vary depending on which print application. The trend is to integrate automation into workflows and hardware, which will increase the OEE of digital equipment. Customers often purchase newer, more efficient Vutek printers that can run multiple shifts at high use, and replace two or three less-productive digital presses.

PW: Nozomi is an interesting figure in the corrugated area.

JJ: EFI has the largest installed base – around 50 Nozomi presses worldwide – in the single-pass inkjet space for corrugated packaging.

We have found that Nozomi presses are capable of driving OEE for both digital and analogue equipment. Customers who also do high-quality flexo or litho lamination can migrate a lot of their work to digital using the Nozomi. They often move jobs that were not very profitable with litho-lamination to digital. Our packaging customers can do this to free up analogue capacity and increase their OEE. Digital production can be ideal for both short- and long-term jobs. It is also very fast and simple to get jobs in and out of production on a Nozomi Press.

PW. India is a price sensitive market. Yet, the trends are always changing. How can a mass producer of goods stay relevant? What innovations in products can one offer consumers to disrupt the market or create new trends?

JJ: From a consumer perspective, digital printing can help brands increase margins in price sensitive areas. Digital also creates a path for smaller brands in the consumer packaged goods space to increase their presence and appeal with shelf-ready packaging that rivals their larger competitors’ offerings. Digital allows for one-to-one versioning and variable packaging to be more appealing to consumers.

PW: Would you consider remanufacturing as an alternative? One Indian post-press equipment manufacturer successfully recycled binderies. What’s your view – advantages versus disadvantages?

JJ: EFI’s large portfolio allows us to meet the needs of customers in terms both budget and productivity. This allows customers to grow from entry-level production to very large-volume work. For some customers looking to enter the market for production display graphics, remanufactured machinery can be part this journey. We have found that remanufactured machinery can help customers to embrace the automation and other improvements in our latest printers. I would view remanufacturing as an entrée for those who want to discover new oceans.

PW: The F&B packaging market in India is expected to grow from USD 33.2-billion in 2020 at a CAGR (compound annual growth rate) of 9.3% until 2026. Based on our basic calculations, India’s consumption of packaged food increased by 200% over the past ten years, rising from 4.3-kg to 8-kg per person annually. The beverage industry is responsible for 23% of all PET packaging applications. India’s consumption patterns are very high. What is the best way to manage a circular economy in such conditions?

JJ: If growth projections you have stated for India continue, there is going to be even more emphasis on sustainability – with fibre-based packaging from renewable and recyclable sources as the key application. The circular economy is part the future economy. This is because digital direct-toboard corrugated packaging printing using EFI Nozomi presses offers real advantages. Nozomi presses use 35% less energy per unit than flexo and Fogra has designated Nozomi technology as the most efficient digital corrugated production system in its class. They are GreenGuard Gold certified and certified for OCC repulpability, recyclability, and virtually no VOCs.

PW: How can you deal with greenwashing as part your sustainability/circular economy communications?

JJ: Because we want our customers make informed, smart decisions about printing solutions, we are very careful with our claims research. For example, in the packaging industry, we worked closely with Western Michigan University in the United States to obtain OCC certification standard for recycling.

Fogra also took the time to analyse how LED technologies compare with respect to energy consumption. Fogra has detailed the energy savings LED curing produces across our packaging and signage portfolios. Fogra discovered that LED inkjet printers produce 82% more energy than other digital printing methods.

PW: India’s Government has set a goal of creating a $5 trillion economy. Your view of India’s potential for the printing and packaging industry, and your company in particular, is it a good place to be?

JJ: That growth trajectory will result in rising Indian standards of living and, consequently, a rise in marketing activities that call for high-quality, vibrant imagery. Over the past year or so we have been excited to see more activity from our partners in India who sell EFI’s wide-format printers in the display graphics space.

PW: The Indian printing industry, especially the packaging industry will experience significant growth as the current USD 3.1 trillion economy becomes a USD 5 trillion economy. According to one number, India’s packaging consumption has increased by 200% over the past decade. It rose from 4.3-kg per capita per annum (pppa), to 8.6-kg per person per year (ppppa) in FY20. Are you ready to support India’s print and packaging industries?

JJ: EFI will continue to work in the print industry with India customers as we have done for decades. This includes collaboration and foster higher productivity, better quality, and more efficient operations. Everything we do, we strive to advance digital print. Much of that has been through state-of-the-art workflows created in our Fiery product line – and many of our innovations from the Fiery business are solutions developed at our facility in Bengaluru.

To keep up with the growth, I believe there will be more demand for digital and automated packaging in the future. India’s packaging industry will want and need to incorporate more digital printing, and not just focus producing more work on existing, legacy analogue production lines. To meet the predicted rise in packaging demand, digital production platforms must be sustainable, automated and efficient.

PW: India’s business leaders are too focused on their machines and investments. Soft power is often overlooked. This includes culture, team-building and delegation. It also covers housekeeping. What’s your view?

JJ: My view is that the technology ecosystem needs to be viewed as a whole, and not just the machines or investments. EFI is proud to share the joy and appreciation our customers feel when they are able, through some of our solutions, to be competitive in entering new markets.

That said, I certainly can and do appreciate the importance of team-building, culture, and delegating; they are essential to EFI’s own success.

Although my career was in printing technology, I spent some time in HR, where I played a key role in team building, recruitment, diversity initiatives, and other aspects of HR. All of this is crucial to the success of any organisation.

EFI’s India Development Centre (IDC) in Bengaluru – which is currently EFI’s largest global facility – exemplifies what we can do in terms of teambuilding and culture. Samir Gulve, the leader of IDC, and his team have made it a highly focused and innovative operation. You can see the strength of the IDC by looking at the many innovations it creates in our Fiery digital frontend and digital workflow products as well as in our IQ suite cloud solutions.

PW: If you have an autobiography, one takeaway from it (if so)

JJ: Two of my lives are intertwined.

My parents formed me as a child and I am proud of what I have become. My wife and our two children are the reason I am the person that I am today. My family sacrifices enabled me to achieve my career. From a professional standpoint, I committed myself each day to our customers as well as to our team members. A career is a marathon that involves daily sprints. I tried to run hard every day.

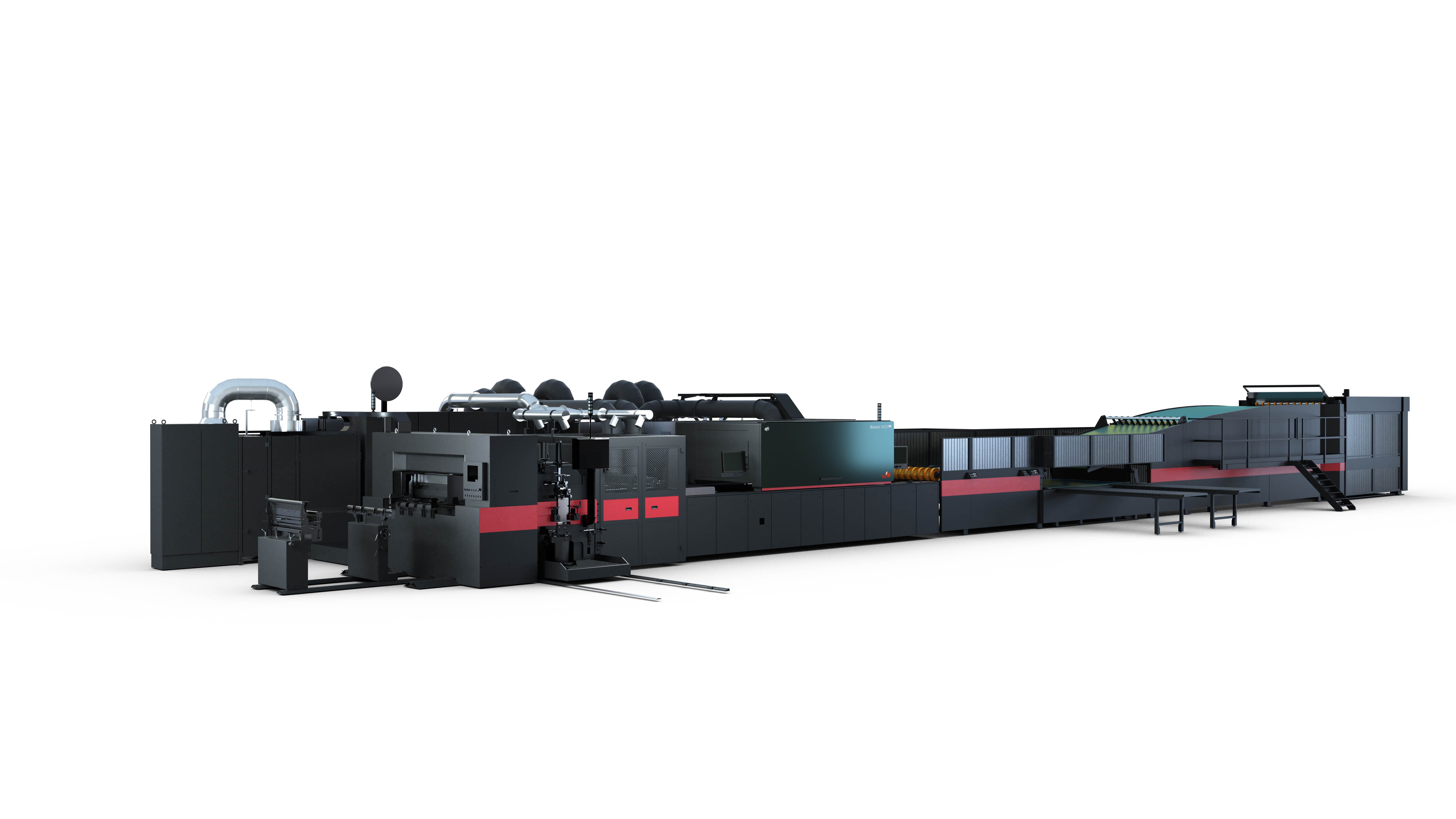

Product Spotlight – EFI Nozomi 14000 LED

The EFI Nozomi 14000LED press is the latest ultra-high speed inkjet solution for corrugated markets. Available this year, the 55-inch-wide press runs at faster speeds up to 328-linear ft per minute with new productivity modes, offering remarkable throughput while meeting corrugated packaging manufacturers’ needs for more compact production lines. The Nozomi14000 LED is a high-quality, uptime-saving packaging machine that can print virtually all board flute types. There are enhancements that allow you to reject damaged boards automatically without stopping production.

The Nozomi 14000 LED press comes in a variety configurations that will suit individual needs. It has a single or double bottom feeder option, a roll coater capable to apply different amounts of primer and an optional varnish station which can provide a range gloss or satin finishes. You also have the option of full or bundle stacker options. Nozomi’s 14000 LED press can be ordered in up to six colours, which includes white.

The new press is equipped with the latest EFI Fiery NZ-1000 digital front end (DFE) and also features the new Fiery system platform – Fiery FS500 Pro – enabling quick processing and colour management at full press speeds.

Fogra Research institute for Media Technologies tested EFI Nozomi singlepass inkjet corrugated technologies against the ISO 20690 energy standards to determine that they are high on power efficiency. Plus, EFI Nozomi is the only single-pass inkjet offering in the industry to have its output certified for OCC recyclability and repulpability by the Western Michigan University Recycling, Paper and Coating Pilot Plant – a leading certification organisation for corrugated recycling.