INTERVIEW Camila Uzcategui, CEO and co-founder, Vitro3D: High Dimensionality Volumetric Additive Manufacturing

The Ahead Formnext 20203D Printing Industry spoke about the winners of this year’s awards Formnext Start-Up challenge.

Camila Uzcategui serves as the CEO and founder of Vitro3D. Her 3D-printing venture was born out of a desire to significantly contribute to global health care. She identified the need for medical devices that are essential in clinics through her experience in NGOs and non-profits. This led her to explore additive manufacturing.

Uzcategui’s academic endeavor led her to a PhD in Material Science and Engineering, concentrating on 3D printing applications, which she accomplished in 2021. Her dissertation focused on characterization of 3D-printing materials aimed at tissue regeneration and engineering. Understanding resins was key to accurately predicting the quality of 3D printed structures.

Uzcategui remarked, “If we are good at characterizing resins, then we can be even better at matching the mechanical properties of these particular types of tissues.”

But rather than work with more established 3D printing technology, Uzcategui’s company has gone towards volumetric 3D printing, or as they prefer to call it, Volumetric Additive Manufacturing.

Vote in the Now! The 2023 3D Printing Industry Awards.

Pioneering Volumetric Additive Manufacturing: Vitro3D’s Strategic Shift Towards Industry-Relevant Solutions

Volumetric additive manufacture is a promising but nascent facet of advanced manufacturing technologies. While the traditional layer-by-layer 3D printing was the focus of Uzcategui’s Ph.D., the exploration into volumetric additive manufacturing came post-PhD during her post-doctoral work, spurred by its potential to surmount challenges like support structures and handling highly viscous resins.

Uzcategui underscored the advantage of volumetric technology over conventional 3D printing methods, stating, “It was awesome to see what challenges that current layer-by-layer 3D printing could not overcome, while volumetric was like, ‘Oh, we’re not worried about that,’ like support structures, for example, or highly viscous resins.” This transition initially unfolded as more of a “passion project,” shifting from standard 3D printing to a technology that efficiently addresses these hurdles.

Regarding the strategic vision, Vitro3D was keen to avoid the typical deep tech startups’ dilemma of being “solutions looking for a problem.” Uzcategui expressed a proactive stance in identifying industries beyond healthcare that could benefit promptly from this technology, acknowledging that realizing the “big dream” of tissue engineering would be a long-term endeavor, likely spanning 5 to 10 years.

Vitro3D now focuses on industries like dentistry and electronics, where volumetric tech could make a big impact in the near future. This pragmatic approach aims at ensuring the company isn’t “raising money for 5 years without revenue” but engaging in meaningful, revenue-generating ventures that edge closer to their ultimate goal of revolutionizing tissue engineering and regeneration.

The Intricacies of Volumetric Additive Manufacturing: A Deep Dive with Vitro3D’s CEO

Uzcategui explained volumetric 3D print manipulation of light at various angles in order to create a 3D model from a digital model. Uzcategui highlighted, “The algorithm is the most important part because that is how we take a 3D virtual object and decompose it in these different angles, and then reproject it, to create a 3D object in the resin. That is all based on a complex algorithm, which generates the projected images.” It is crucial to account for material properties and the resin’s reaction to light, ensuring the resin receives the precise amount of light for polymerization. This capability is only possible with the software.

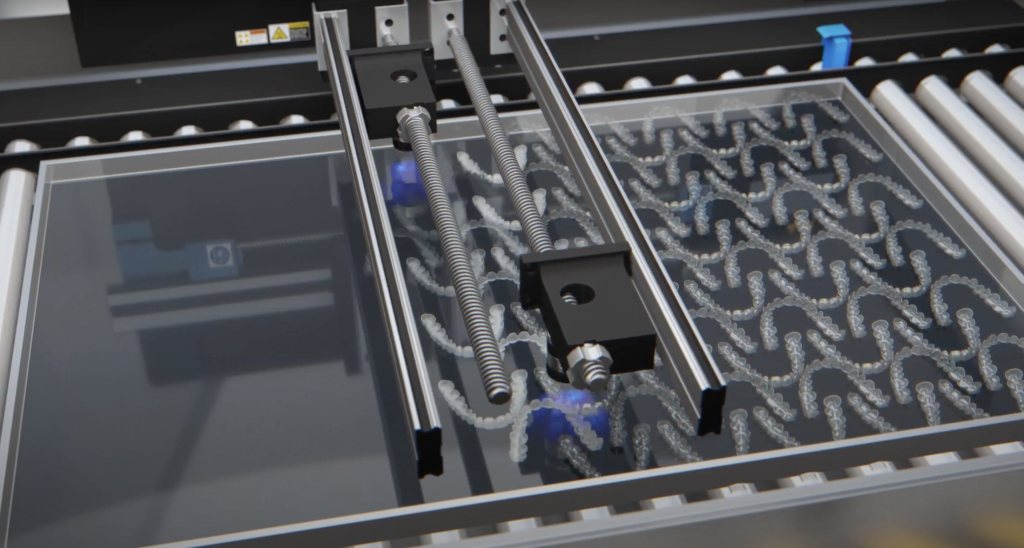

Uzcategui explained that Vitro3D had invented a high-dimensionality volumetric additive manufacturing (HD VAM) method, which uses a two-dimensional cone to translate, and thus input four dimensions of data into the material, as opposed the three conventionally. She noted, “We call it high dimensionality VAM because rather than just inputting three dimensions of information via rotation and a two-dimensional image, we’re putting four dimensions of information through translation in X and Y and a two-dimensional cone of light containing information.”

A laser is the most common light source. This light source is critical for a high-quality, long-focus light that can be projected through the entire space. Uzcategui stated, “We want our depth of focus to be as big as possible, starting with 3 cm.”

Uzcategui, who addressed the inherent size limitations in volumetric 3D print due to the depth dimensions, explained how the HDVAM method decouples dimension. This allows for greater dimensions in X andY while maintaining a small depth dimension. Vitro3D’s approach has an eye on broader industrial applications.

Scaling Volumetric Additive Manufacturing: Vitro3D’s Exploration into Larger Dimensions and Material Versatility

The company continues to work on determining the maximum size of printing possible using its technology. The current maximum stands at a diameter of eight centimeters, though Uzcategui hints at a tantalizing vision, “Could we have a cartridge the size of a desk rather than having a box? Could we have some sort of gantry system that can be installed in a manufacturing plant?”

This innovative approach is designed to seamlessly integrate the HDVAM process into existing production lines. It could usher in a new age of large-scale, on-site additive manufacturing. Central to this endeavor is their proprietary algorithm, described by Uzcategui as the “magic” behind their technology. This algorithm mimics the printing process, before it starts. It ensures that the resin is polymerized only where the user wants. Uzcategui explained, “The algorithm takes in information about the material, the optics, and the mechanics and simulates the printing process.”

The conversation highlighted a significant advantage of volumetric 3D printing—its aptitude for handling highly viscous resins, a challenge for conventional layer-by-layer systems. The resin flow is a bottleneck in standard systems. This is especially true for resins that are highly viscous. However, Vitro3D’s technology bypasses this hurdle. Uzcategui elaborated, “Because no resin flows during the printing process, it’s just a static volume. We don’t care if the material is a solid. Regarding our viscosity limitations on the higher end, we haven’t found any so far because we’re not limited by material flow..”

Vitro3D’s pursuits reflect a compelling trajectory towards surmounting existing barriers in 3D printing technology, heralding a paradigm shift in how additive manufacturing integrates within traditional production environments.

Vitro3D tackles novel material challenges in 3D printing

Certain resins that are essential for electronic components or connectors can be difficult to print with traditional 3D printers due to their viscosity. Uzcategui remarked on a particular case where a firm had to innovate around this challenge, “They had some success with their printer because they heat these viscous resins.” This example underscores the workaround necessitated by the limitations of existing layer-by-layer printing techniques when dealing with such materials.

Uzcategui also highlighted the fact that nano gels are finding use in the dental industry, which is also a challenge with viscosity. The viscosity of nano gels increases as they are loaded, requiring innovative processing techniques to efficiently handle them.

Vitro3D’s HD-VAM technology emerges as a promising solution, aptly suited to process these innovative yet challenging materials without the need for additional heating or modified chambers, as required by some layer-by-layer printers.

This advantage is not limited to the printing stage, as volumetric printing allows the object to be printed simultaneously. It also extends into the post-processing phases, which are often bottlenecks in overall production schedules.

Uzcategui explained, “We have a huge advantage in speed because the part materializes at once, and you’re not going layer by layer, so a lot of the time, you’re cutting your speeds per part very significantly.” This speed enhancement is pivotal as it directly impacts the production lead time, a critical factor for industries aiming to reduce time-to-market.

In addition, she discussed the importance of post-processing. The absence of support structure in volumetric 3D-printing reduces post-printing cleaning time. She mentioned, “You’re printing without support structures or with very limited support structures in a different way that, layer by layer, 3D printing just can’t access.”

Uzcategui also touched on an essential point about ensuring quality and repeatability across parts, stating, “A huge focus of our company is to automate post-processing to get more reliable parts, not only in the printing but in the material properties themselves.”

Vitro3D’s approach towards not just accelerating the printing process but also streamlining post-processing reflects a holistic understanding of industrial production needs.

Cost Efficiency in Volumetric Additive Manufacturing: Vitro3D’s Software-Centric Approach

Vitro3D wants to provide a cost effective approach to 3D-printing. The focus is on intelligent software, not expensive hardware. Uzcategui stated that their system is not as expensive as some 3D-printing setups, which can cost up to one million dollars. Instead, it uses hardware similar to that used in layer-by-layer 3D-printers. The key difference is their proprietary algorithm which drives the 3D volumetric printing process.

The software-centric method, she says, allows not only for lower hardware costs but also the creation of custom hardware tailored to meet the customer’s specific needs. Uzcategui adds, “We believe in an open resin system that allows customers to use their own materials in our HD-VAM system, where the material only needs to be certified by Vitro3D and added to the algorithm’s material library.”

The main value proposition, as per Uzcategui, revolves around “providing software-based solutions” aimed at accelerating development in a manner that hardware alone can’t achieve. She added, “Our combination is more of a low-cost hardware,solution-based software approach, rather than trying to sell a piece of equipment for hundreds of thousands of dollars with service fees..”

Volumetric 3D Printers: Challenges and Potential

Volumetric 3D printing is still in its infancy. It has limitations, primarily with regards to resolution and size, which are a cause for skepticism. Uzcategui remains optimistic. She believes that, despite the limitations of their HD-VAM 3D printing technology, it holds promise to solve significant challenges for certain industries. These challenges are out of reach of existing 3D printers.

Uzcategui highlighted the growing restrictions on the use of ‘forever chemicals’ like PFAS and PFOA in Europe, restrictions she anticipates will soon be a global norm. She stated, “We can use highly viscous resins that can often have better material properties when it comes to toughness,” making volumetric 3D printing a likely candidate for creating alternatives to these chemicals.

Uzcategui explains that one of the most important advantages of volumetric 3-D printing is its ability to disrupt the traditional manufacturing process. Uzcategui illustrated this with the example of creating a simple electronic plug, pointing out that currently it takes multiple steps to cover metal in plastic. However, with volumetric 3D printing, one could “have a bunch of metal pieces inside of a cartridge, and then we can create a part around that metal,” eliminating several manufacturing steps, reducing waste, and potentially speeding up the iteration of new technology designs.

The discussion moved on to overprinting or overmolding. This is where volumetric 3-D printing excels, with its ability to create low-volume high-mix parts. Uzcategui believes this is a great way to iterate quickly on new technologies, without the heavy financial burden that comes with tooling.

The intricacies of ensuring precise material behavior amidst a maelstrom of moving resin that’s constantly changing and shrinking demand a profound understanding and meticulous control of the light-material interaction. She highlights that the process is “dependent on understanding and crossing that gelation threshold,” indicating a razor-thin margin for error.

Uzcategui, citing the success of Carbon, a company that has invested heavily to understand how materials interact light, highlights the importance of this interaction for volumetric additive manufacturing. “In our case, we have a multidimensional process where the light-material interaction is even more important than layer-by-layer 3D printing,” she associated with standard manufacturing methods like injection molding.

Vitro3D has its sights set on commercialization and is currently in discussions with early-adopters for pilot projects scheduled for the end of 2024. The startup’s journey toward commercialization is anchored in a collaborative ethos, aiming to work alongside industry players to craft solutions that address specific manufacturing hurdles.

As a fledgling startup, Vitro3D is also on a quest for industry talent and collaborative partnerships, a mission Uzcategui hopes to advance at the upcoming Formnext expo, one of Europe’s premier 3D printing events. There, she aims not only to showcase Vitro3D’s technology but also to forge connections in industries where their technology could resolve persistent manufacturing challenges.

Uzcategui sees the burgeoning interest and entry of other players in the volumetric 3D printing space as a testament to the technology’s growing legitimacy. She posited, “It’s awesome to see that there are other volumetric 3D printing companies out there and that we’re all solving challenges in very different ways. Not only does everybody have their own way of doing it, but we each have unique benefits.”

Vitro3D, with its tailored approach, is a step closer to becoming a disruptive force for industrial technology. It meets customers where they are, and their needs.

Make sure to visit Vitro3D during Formnext 2023; find them in Hall 11.1 at booth B55C.

What is the Meaning of the Future of 3D Printing What does the next decade hold?

What is the best way to get in touch with you? engineering challenges What challenges will the sector of additive manufacturing face in the next decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry Newsletter Follow us on TwitterLike our Facebook page Facebook.

While you’re here, why not subscribe to our YouTube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Do you want to work in the additive manufacturing sector? Visit Jobs in 3D printing Check out the following roles.

The featured image is a prototype HD VAM system in the Vitro3D Boulder lab. Photo by Vitro3D.