PRINTING United Does Not Disappoint!

United Expo 2023, a wonderful event. The convergence model allowed for new product opportunities and expansion to be considered. Even with the drupa in the background, there were many product introductions and revisions.

The following is a brief overview of the Overview

United Expo 2023 in Atlanta just ended, and it looks like it was a huge success. It seems that the convergence model, which is based on this event’s structure, allows print service providers to consider and see new opportunities for product expansion and convergence. The event was divided into two large halls. Each one focused on a specific print service or equipment. Hall B featured booths that were mostly focused on commercial printing, packaging and large-format graphics. Hall C was home to booths displaying large-format graphic equipment, as well as textiles, direct-to garments, direct-to shape, software and many other booths.

The show was well-attended with registration rates comparable or slightly above last year. We are still waiting for the final figures. I spoke to many exhibitors and they all expressed their satisfaction with the show. I also spoke to many attendees, who were very satisfied with their visit. The educational content was just as important as the equipment. If there were any negatives, it really centered around the size of the exhibit floor and the amount of “steps” people were putting in each day. In all fairness, there is no way to present an event with this scope in a smaller venue, and from my understanding, next year’s event in Las Vegas will be even bigger, so get better shoes!

The show was well-attended with registration rates comparable or slightly above last year. We are still waiting for the final figures. I spoke to many exhibitors and they all expressed their satisfaction with the show. I also spoke to many attendees, who were very satisfied with their visit. The educational content was just as important as the equipment. If there were any negatives, it really centered around the size of the exhibit floor and the amount of “steps” people were putting in each day. In all fairness, there is no way to present an event with this scope in a smaller venue, and from my understanding, next year’s event in Las Vegas will be even bigger, so get better shoes!

Highlights in Print and Packaging

At PRINTING United, there were many new and reintroduced products. While I can’t cover them all, I will attempt to identify some of the ones I found most interesting, primarily on the commercial print and packaging side. There are still a few I didn’t get to, so we’ll have to do it again!

Fujifilm was the largest booth at the show, and with good reason. This was their “coming to North America party.” While the Fujifilm Graphic Communications Division has had a presence in North America for decades, it has been primarily in offset and flexo plates, inks, chemistry, wide-format printers, and support. In 2016, they launched the first J Press production inkjet cut-sheet press in North America. Fujifilm was able to enter the North American market this year with its entire line of inkjet and toner presses after the dissolution of 58-year old Fuji Xerox.

They announced first their fourth-generation J Press 750HS sheetfed inkjet printer, with speeds of 3,600 sph or 5,400. They did display samples of their J Press 790 aqueous flex packaging press, but not on the actual floor. Then they presented the new Apeos brandingTM Revoria Press has introduced the Series toner printers for enterprise-level and entry-level applications.TM They are also using toner presses for production. Some of these may look similar because they were previously sold under the Xerox brand.

The Revoria Press is a toner cutter sheet that was introduced by them.TM GC12500. This was quite a surprise since the inherent wisdom was that you couldn’t make a toner press with a print width beyond 13 in. This four-color machine can print at speeds up to 2500 B2sph with a resolution of 2400 x 2,400dpi. It supports a media range of 64–450 gsm stock with a maximum sheet size of 26 x 29.5 in.

Revoria PressTM GC12500

Also, they showed off their Revoria Press PC1120. This is the same engine six-color used in both the Xerox Iridesse Color Press and Sharp BP-1200S Color Press. Xerox signed an agreement with Fujifilm, allowing it to continue selling their products under the Xerox label. This will allow them to maintain their current printer line. We’ll see more companies, such as Xerox or Sharp, licensing Fujifilm products.

Revoria Press PC1120

This isn’t surprising since there are many press manufacturers licensing press hardware from other manufacturers. Ricoh licenses its cut-sheet inkjet presses from Kyocera. EFI licenses some wide-format. Each OEM implementation adds value to the press.

Xerox might not be attending drupa this year, but their booth was impressive with the Iridesse (see below) production press as well as their Baltoro HF Inkjet Press. After the recent restructuring of their corporate structure, they are expected to return to developing and selling new press hardware very soon.

Ricoh Pro Z75

Speaking of Ricoh, they “officially” launched their Ricoh Pro Z75, a 4,500 sph duplexing B2 cut-sheet production inkjet press. Also, they announced the updated Ricoh TotalFlow® Software for producers. Ricoh’s cloud-based solution is a unique approach. This scalable solution manages print workflows, from prepress to print and finishing.

Sharp has expanded its production from in-plant and enterprise to full production, with the introduction of BP-1200S. The company is now working closely with its distribution channel to help them meet the new market requirements, as well as sell and support these products.

SCREEN has officially launched the Trupress® PAC 830F. It is a 830 mm wide, aqueous-based flexible packaging machine that runs at 75 mpm. The first installation was announced by Chiyoda Gravure Corporation, Tokyo, Japan. SCREEN showed its TruePress L350UV, Screen, and Screen Pac 520P a flexible packaging paper press.

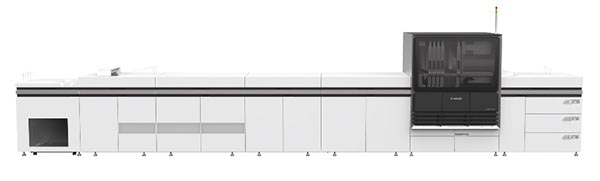

Canon iX1700

Canon showcased their expanding V Series toner presses, as well as the iX1700B3 duplex cut sheet inkjet and LX2000 label inkjet. The company also highlighted their large-format products, including the Colorado-M Series, the Arizona 2300 Series, and imagePROGRAF. These devices are capable of displaying innovative solutions, from textiles to signage.

Durst showed their Tau RSC platform label printer, as well as their extensive wide-format printing line. This production inkjet isn’t just for labels. It can also print flexible packaging. UV inks are available for a variety of flexible packaging and label substrates. They also demonstrated their HAWK-EYE, a closed loop intelligent system to compensate nozzles.

Heidelberg didn’t have any offset presses on the floor this year, although they did have a customer event at their US headquarters the day before PRINTING United. The new Gallus One inkjet/flexible packaging/label press was displayed instead.

RMGT 970PF

RMGT displayed the North American launch of the RGMT 960PF 8-Up+ color perfecting press in a booth measuring 50 feet. The 4/4 perfecting presses supports a sheet size of 25 x38-in. Prints up to 15,000 sheets per minute. The press displayed was configured with RGMT UV LED curing, a technology Ryobi created for sheetfed printers. It was introduced at drupa in 2008 along with Toyo Inks and Panasonic Lamps. It also had the RGMT Automatic Smart Assist printing system. This means, in essence, that the press will run independently from job to task to task without any operator intervention.

HP had a wide-format press line on display, as well as an offsite event the day before at their Graphic Experience Center for those who wanted to see HP’s production print equipment.

Agfa Onset X

Agfa was displaying their Onset X upgradeable printer. It is the only flatbed wide-format, high-productivity printer on the market. It can print more than 15,000 square feet an hour and is designed to run continuous 24/7 production configured with “Hal,” their automation robot. The eight channel Onset X1 can be configured in CMYK, plus LcLmWO. When your production needs grow, it can be upgraded to the Onset X2 with an additional carriage of six channels (to add a second set CMYK). Then transformed into a top of the line Onset X3 (three x CMYK and W or O).

Enfocus launched their new Enfocus Review. This cloud-based workflow provides accurate and quick PDF viewing within the browser. Overprint and color spaces are two common causes of inaccurately rendered pdf. The software integrates Switch and Pitstop seamlessly and is compatible with Enfocus’ newly launched cloud. As with many other workflow software providers, they are slowly moving to the cloud.

Finishing

It wasn’t all about presses, there was a lot of new finishing equipment there as well. Folding cartons make sense for PSPs who are looking to increase their product range. In line with that, KAMA showed their ProCut 76 Foil Packaging for embellishment, die cutting, stripping, and blanking and the fully automatic FlexFold 52i folder gluer.

SEI LabelMaster

Matik SEI Laser demonstrated their LabelMaster continuous-feed CO2 Laser system on the marketplace. It can perform laser processes such as cutting, scoring and marking, micro-perforating or versioning in one pass. The 63-in. Mercury Wide-Format Laser Cutting and Marking system cutting acrylic, although it’s a very flexible platform that can cut PMMA, acetates, ABS, plastics, micanite, wood, leather, paper, cardboard, and textiles. It operates at 2 Gs of acceleration, one of the fastest plotters available—yet isn’t as fast as their X-Wave platform, the fastest plotter in the world, which operates at 10 Gs of acceleration. It is four to five time faster than the traditional zone plotter.

Bowe Systec Fusion Speed

Bowe Systec has launched its flagship Fusion Speed Boxit Mail Tray Automation. The Fusion Speed BOXIT Mail Tray Automation system is the fastest and can process up to 30 000 letters per hour. The automatic traying system can be fully automated. Rolls of paper are stacked in front, then loaded into #10 or 6×9-inch trays. In the hoppers are envelopes. Sorted and filled trays come out at the end. The speed makes it almost impossible for an operator to keep up with so that’s where the BOXIT automation comes in. Each postal tray is filled in 30-40 seconds.

In conclusion

Many people question if the large trade show has lost its relevance. The answer, from my perspective, is a resounding no. The events also serve as a platform for networking, and the preservation of industry heritage. Although some events might not have enough to offer, or be sufficiently different, the majority of attendees and exhibitors see value in these events. It is likely that some events will need to be realigned in the future, but this is a great thing. Doing the same thing over and over isn’t necessarily healthy or beneficial. Looking forward to next year’s PRINTING United Expo in Las Vegas, September 10–12, 2024.

More to Come…

The pace of 2023 has increased, and drupa 2020 is beginning to show its face. I would like to address your interests and concerns in future articles as it relates to the manufacturing of Print, Packaging, and Labels, and how, if at all, it drives future workflows including “Industry 4.0.” If you have any interesting examples of hybrid and bespoke manufacturing, I am very anxious to hear about them. Please contact me via [email protected] Contact us with questions, ideas or interesting examples.